OUR SERVICES

Sujo Plast has been at the forefront of providing manufacturers with high-quality plastic injection moulding products. We do this through in-depth research, tests, and development processes in the moulding technology. Working with a team of highly trained and experienced technical specialists and engineers, we have been providing manufacturers from different industries with top-quality products for over 28 years.

We have developed our infrastructure to make Sujo Plast a one-stop service provider for all your plastic moulding requirements.

Injection Moulding

In injection moulding process, plastic granules are smelted and injected into a mould at very high pressure to obtain the specified shapes. The part is then cooled and removed from the mould.

Plastic injection moulding is the oldest service on our portfolio and forms the foundation of Sujo Plast. We have invested in advanced modern injection moulding machines from manual types to today’s fully automated machines. Sujo Plast offers injection moulding services with the ABS, SAN, PC, PA 6 GF, PA 66 GF, TPU, PP, PPCP, POM, PBT, PVC, and many other materials.

Our injection moulding service caters to the requirements of manufacturers from different industries, including automotive, electronic appliances, healthcare, home-use plastic components, et cetera.

In injection moulding plastic granules are smelted and injected into a mould to obtain specified shapes.

Our injection moulding services entail a variety of processes that also includes value additional methods to meet our client’s requirements. Our facilities are built to cater to the unique needs of clients’ plastic mouldings. We can provide the basic product engineering process to complete product development to support the manufacturer’s processes.

We have over 20 fully automatic injection moulding machines each equipped with different technologies including hydraulic and electrical machines that can handle up to 1300 tonnes. Our machines come with top-notch axillaries such as pick-and-place robots, auto material feeders, temperature regulators, chillers, and more.

Insert Moulding

Insert moulding is a revolutionary manufacturing process that can produce complex and intricate parts and products with greater accuracy and speed than ever before. Sujo Plast has invested in complex machinery and expertise to help manufacturers produce intricate products through our insert moulding services.

What sets insert moulding process apart from other injection moulding techniques is the ability to insert a piece or pieces of metal or other material into the mould that can then become part of the finished product. This allows for the creation of parts with embedded metal components, like hinges, clasps, and fasteners.

It also makes it possible to create parts with varying levels of hardness and durability. The possibilities are endless, and insert moulding is quickly becoming a popular manufacturing method for a wide range of products. Plus, it’s cost-effective making it a great choice for businesses looking to create high-quality products with minimal cost and waste.

Get in touch with us and discover how our insert moulding service can shorten your production timeline and save you more money.

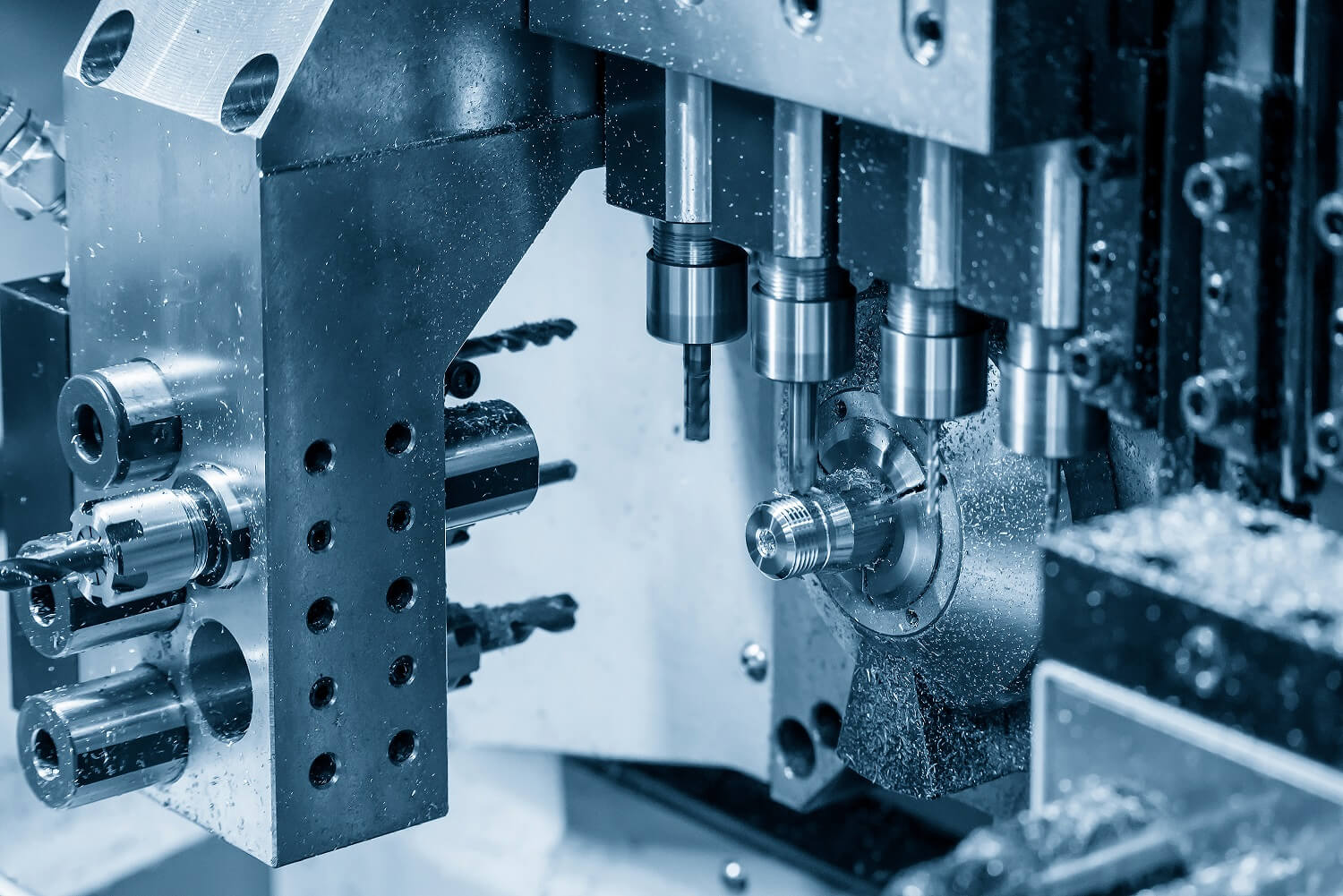

CNC Precision Turning

Sujo Plast introduced precision turning operations into its portfolio in February 2023. We invested in a highly precise swiss lathe. It is a five axis machine with three axis on main spindle and two axis on sub spindle for overlapped machining of front and back side. Our large capacity barfeeder enables high volume production of turned parts.

The machine is capable of complex work piece machining in single setup using cross drilling milling facility and C axis.

Ultrasonic Welding

Sujo Plast introduced Ultrasonic Welding into its portfolio in 2020 and has taken great strides to perfect the service. Today, this process has formed an essential part of our services, offering manufacturers an excellent replacement for glue and screws.

The process makes use of high-frequency ultrasonic vibrations where the welding creates a melting point in between materials to produce a joint free of adhesives or joining substances. Simply put, Ultrasonic Welding joins injection moulded components together without adhesive materials.

Our process creates a strong bond at a molecular level but within the welding seam. Since the process takes less than a second, we have been employed in the mass production of automotive parts, consumer products, and more.

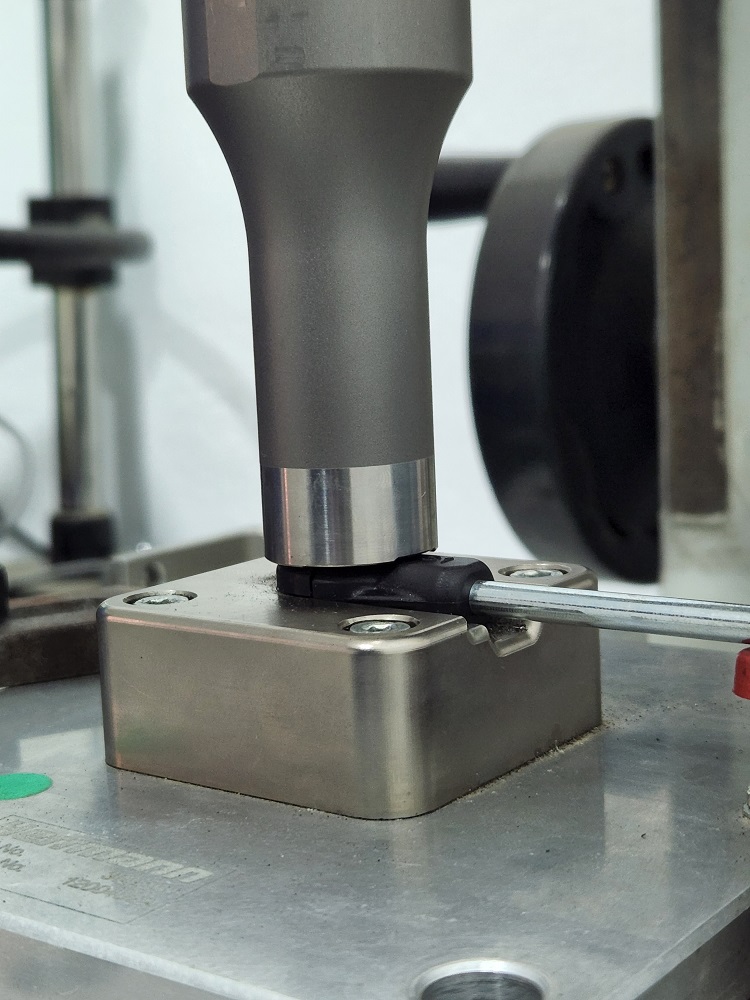

Orbital Riveting

Sujo Plast also specialises in orbital riveting consultancy services. As manufacturers’ need for a orbital riveting process grew, we decided to introduce the service into our portfolio to cater for their requirements. Today, we have invested in highly advanced production equipment and machinery to offer orbital riveting services.

If your core business is manufacturing, you understand that orbital riveting is a solid way of neatly joining two metal pieces. Our orbital riveting process is safely implemented and effective to produce tight rivets. This makes it a preferred method of joining t wo metals in a wide variety of industries.

We have modern cold-forming machines that rotate at supersonic speeds while exerting a downward pressure on metal to shape them as required. During the process, we first thread the rivet into the pieces of metal to be joined. Next, the peen applies a downward force on the metal rivet while rotating to create a uniform shape. Contact us today to discuss how Sujo Plast can help you efficiently perform orbital riveting tasks.

Pad Printing

Are you looking for a mass pad printing service provider? Sujo Plast has the right machinery, expertise, and resources to carry out high-quality pad printing. Our process is a versatile, cost-effective and quick process that can be used to print on a wide variety of surfaces such as plastic, metal and ceramics.

It can be used for highly precise prints and is perfect for both small and large production. It uses an ink pad to transfer the printed design onto a receiving surface. Since we introduced this service, it has grown to become one of the most sought-after services we offer. Pad printing can be applied to an entire object or just to selected areas.

If you want to create vibrant, durable, and unique designs, Sujo Plast offers the solution through our top-notch pad printing services. We serve clients from a wide range of industries, including healthcare, automotive, toys, and more.

Mould Making

Sujo Plast prides itself on high-quality mould-making services. We can attain an accuracy tolerance of up to 20 microns. This means that our moulds are highly dependable and can be used in the manufacture of automotive parts, plastic food containers, plastic PVC fitting moulds, plastic toy injection moulds, and more.

Our process is efficient and cost-effective, allowing us to create moulds according to your 3D product drawing. This can in turn save you money and time in the production of parts and plastic products.

Customised Product Assembly

Customised product assembly is the new trick that companies use today to cut down costs while spending less time in production. Sujo Plast offers cost-effective product assembly services, customised to your unique requirements. We have invested in highly advanced facilities to assemble products.

We utilise a collection of highly innovative techniques and expertise to complete product assembly processes to your satisfaction. Every assembly job begins with a well-organized workstation and setups to complete the assembly process on time while meeting client requirements. We have invested in workstations fully equipped with machinery to efficiently complete product assembly processes that are labour-intensive.

At Sujo Plast, we are committed to excellence, and we have automated our services where necessary to ensure only quality products and services are rendered. Contact us today and let us help you cut down your production bottlenecks.