Quality Capabilities

Sujo Plast is a brand name that is synonymous with quality. We never take second guesses and uncalculated moves when it comes to maintaining our quality threshold. And that is why we have strict guidelines, procedures, and processes developed by the industry’s best minds to ensure quality is never compromised.

For over 28 years, we have consistently improved our practices, infrastructures, and policies to adhere to global market standards. There will never be a time when we hold back to these ideals because our customer satisfaction guarantee is what keeps us running.

How Sujo Plast Maintains The High-Quality Levels

Our adherence to the quality standards of the market is something we have built over the years. This is how we manage to maintain unmatched quality levels:

Endless quality management processes

At Sujo Plast, we understand better than anyone why quality should never be compromised. And that is why our process of quality management is a never-ending one. we ensure our processes of securing, controlling, and enhancing product quality have no boundaries.

That has made it possible to continually supply our clients with upgraded products each time as the competition and environment keep changing.

Quality control

Product quality means everything to us, which is why we have a dedicated team tasked with ensuring all production processes meet the required quality standards. The program spans the entire company and includes all business aspects. Every departmental head and team leader is tasked with ensuring that our quality policies are strictly adhered to.

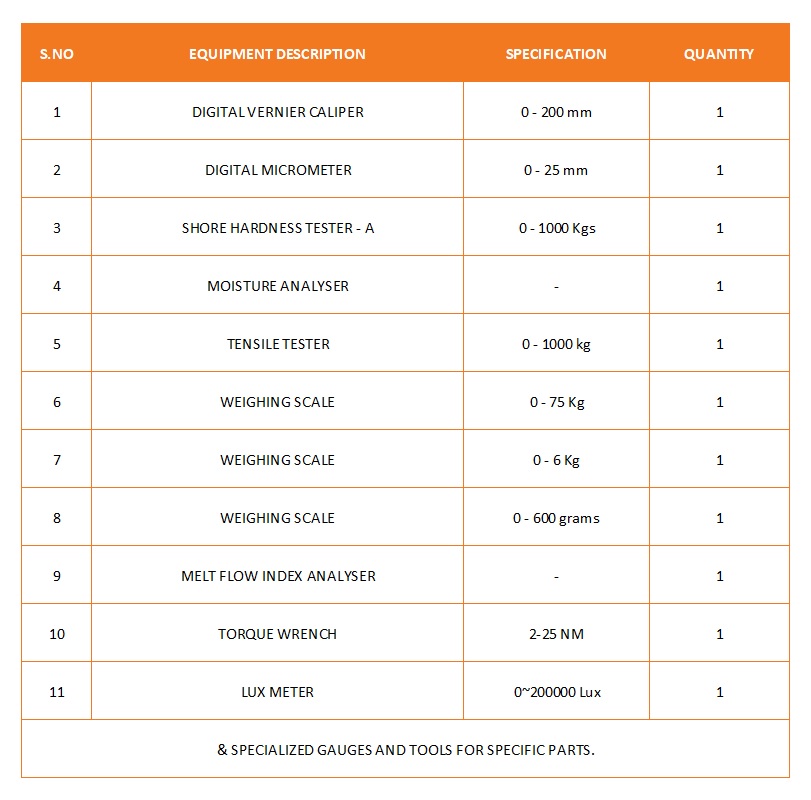

We have capacitated every team at Sujo Plast with the right tools, equipment, machines, and expertise to ensure quality requirements are met every time.

Compliance management

We have compliance management in place to regulate processes and verify that the company is compliant with the applicable business norms, standards, and rules. To prove this to our customers, we have successfully acquired different certifications including the ISO 9001:2015 and SQ Certification.

Quality standards verification

Having policies in place alone is not enough, we have also put in place auditing practices to ensure the set quality standards are met every time. Sujo Plast does not follow a single approach or methodology during the assessment, but we develop and set our practices to be compliant with the industry’s quality requirements.

We carry out inspection routines right from the moment raw materials are received, to when product dispatch is done. Throughout the quality standards verification process, we carry out Critical to Quality (CTQ) dimensions identification and inspection.

Every production process is accompanied by the clients’ quality documents to ensure nothing goes against the stipulated requirements. The quality verification process continues throughout until when the dispatch to the client is done. Every client receives a pre-dispatch inspection report (PDIR) against every delivery.

Sujo Plast is dedicated to offering your organization credibility and reputation by working closely with your team in an efficient manner. Every step of the production process is monitored and approved so that it meets the required quality standards before moving to the subsequent phases.

Kaizen

Kaizen activities (continuous improvements) are regularly done with active participation from the entire workforce. The improvements though small are done regularly. These small regular improvements are done with long term focus in mind. We staunchly believe that there is space left for improvements even in the perfect system.

Measuring and monitoring equipment